Image Source: Google

When it comes to metal fabrication, precision is key. The bending machine is a vital tool in achieving flawless results, allowing you to create accurate bends in metal sheets with ease. Mastering the bending machine requires skill, practice, and an understanding of its capabilities. In this article, we will explore the art of precision bending and provide you with tips to help you achieve flawless results every time.

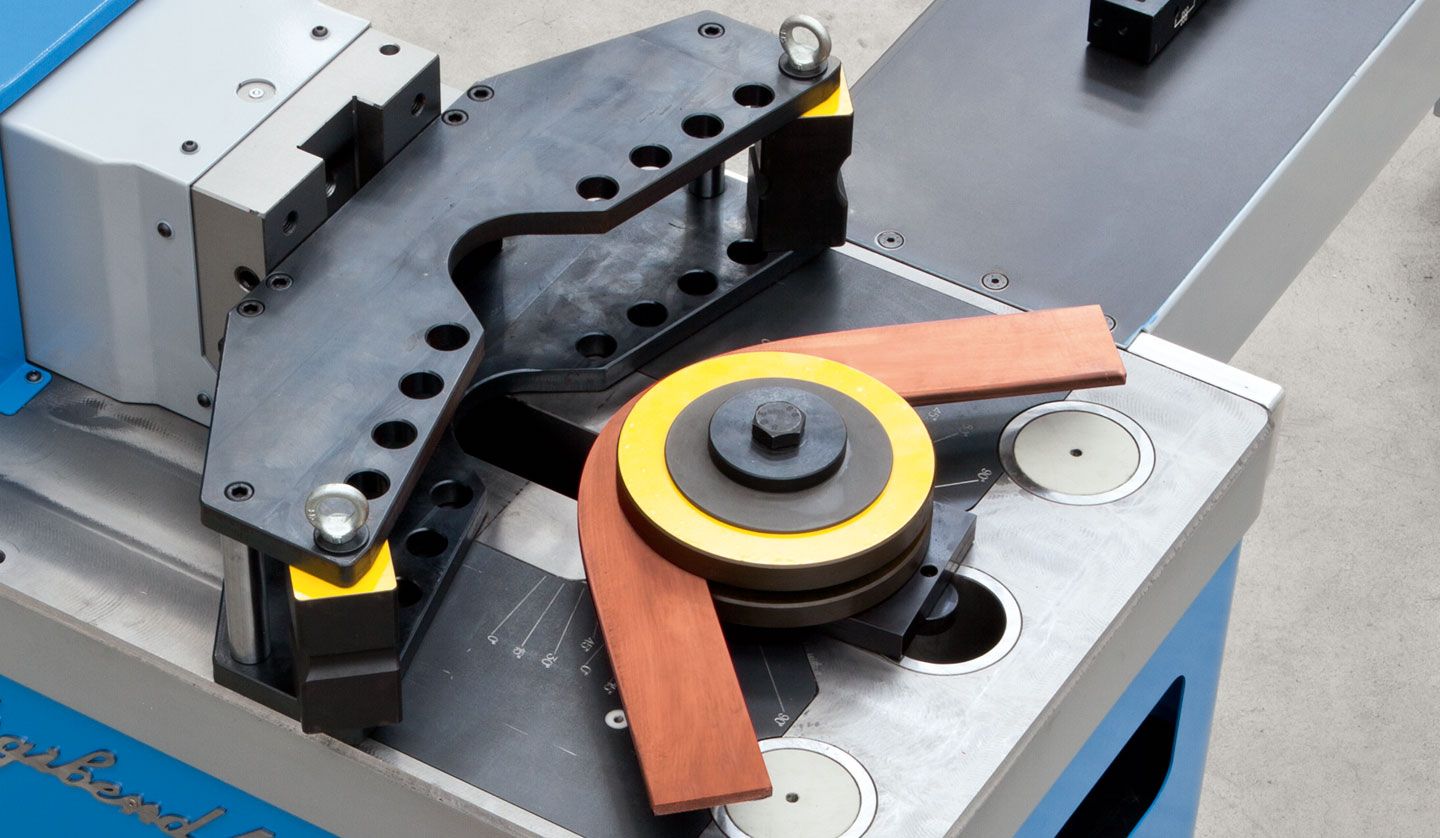

The Basics of Bending Machines

Before diving into mastering the bending machine, it's essential to understand the basics of how these machines work. Bending machines use a set of dies to bend metal sheets into specific shapes and angles. The machine applies force to the metal sheet, causing it to deform and take on the desired bend.

Types of Bending Machines

- Press Brake: A press brake is the most common type of bending machine, using a hydraulic or mechanical ram to bend the metal sheet.

- Roll Bending Machine: Roll bending machines use a series of rollers to bend the metal sheet into cylindrical shapes.

- Tube and Pipe Bending Machine: These machines are specifically designed to bend tubes and pipes into various shapes and angles.

Factors Affecting Precision Bends

- Material Thickness: Thicker materials require more force to bend accurately.

- Die Selection: Choosing the right die for the desired bend angle is crucial for achieving precision.

- Machine Settings: Proper adjustment of machine settings such as pressure and backgauge position is essential for accurate bends.

- Operator Skill: Skilled operators can make real-time adjustments to ensure precision in bending.

Tips for Mastering the Bending Machine

Now that you have a good understanding of how bending machines work and the factors that affect precision bends, let's explore some tips to help you master the art of precision bending:

1. Know Your Material

Understanding the properties of the metal you are working with is crucial for achieving precise bends. Different metals have varying strengths and elasticity, which can affect how they bend.

2. Choose the Right Die

Using the correct die for the desired bend angle is essential. Improper die selection can result in inaccuracies and imperfections in the final product.

3. Adjust Machine Settings

Take the time to properly adjust the machine settings such as pressure, backgauge position, and bending speed. These settings can greatly impact the precision of your bends.

4. Practice, Practice, Practice

Mastering the bending machine takes practice. Experiment with different materials and bend angles to hone your skills and improve your precision.

5. Inspect and Measure

Always inspect your bends and use measuring tools to ensure they meet the required specifications. Make any necessary adjustments to achieve the desired precision.

Benefits of Mastering Precision Bending

Mastering the art of precision bending offers a wide range of benefits, including:

1. Improved Quality

Accurate bends result in high-quality finished products that meet or exceed customer expectations.

2. Increased Efficiency

Precision bending reduces the need for rework and corrections, leading to increased efficiency in the fabrication process.

3. Cost Savings

By producing flawless bends the first time, you can save time and materials, ultimately reducing costs in the long run.

4. Enhanced Reputation

Consistently delivering precise bends establishes your reputation as a reliable and skilled metal fabricator.

Conclusion

Mastering the bending machine is a crucial skill for any metal fabricator looking to achieve flawless results. By understanding the basics of bending machines, practicing with different materials, and following the tips provided in this article, you can enhance your precision bending capabilities and take your fabrication work to the next level.